Discrete Digital Clock Manual

Overview

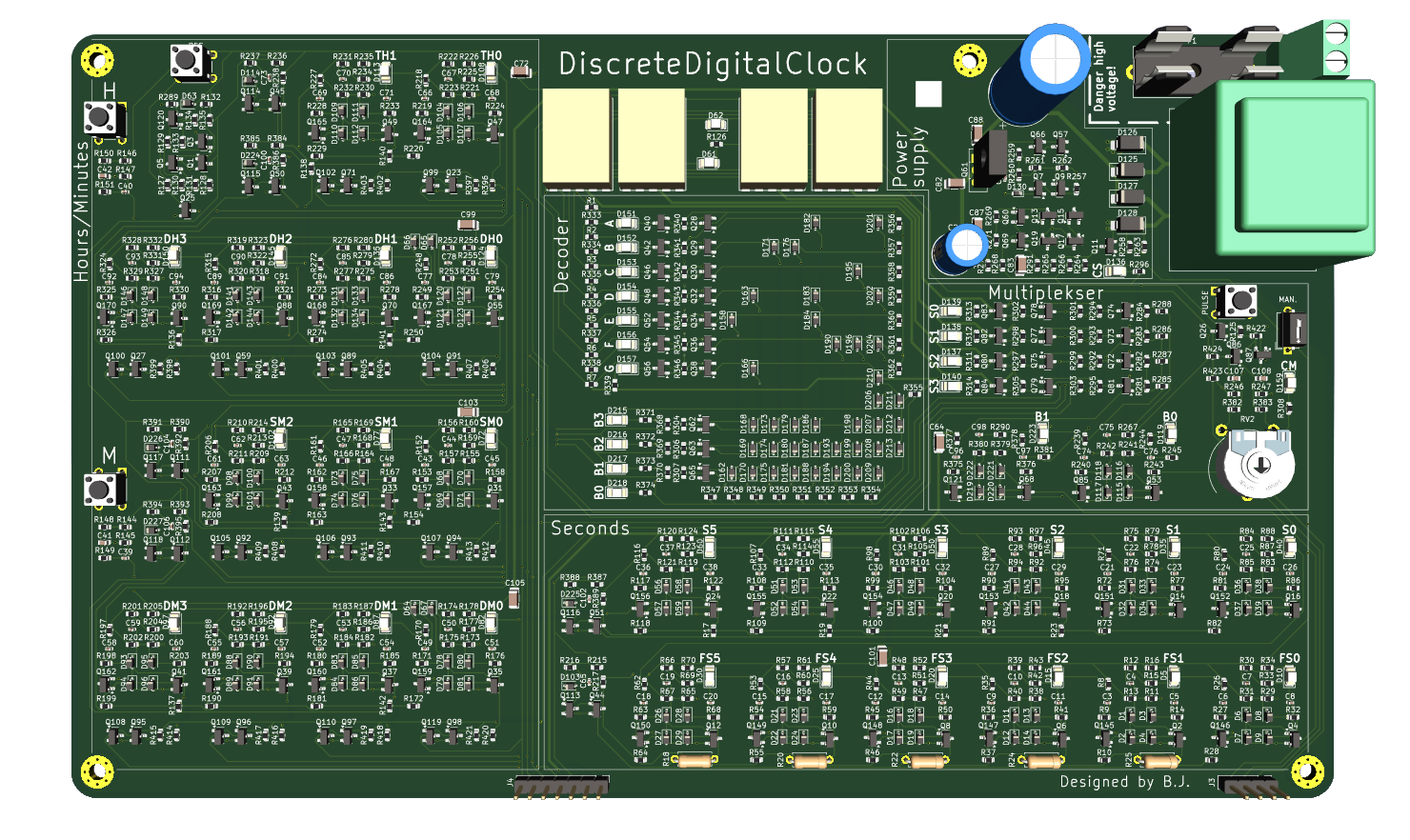

This clock is an enlarged version of a logic IC, designed entirely from discrete components. It’s a fascinating way to see what’s inside a typical clock counter IC. The design is optimized for discrete components and simplified to use a relatively small number of parts.

The clock has four 7-segment displays that show a 24-hour time format with minutes. It also includes indicator LEDs for all counters, allowing you to see the binary values of hours, minutes, and seconds.

What makes this clock especially interesting is that it uses only basic components—transistors, resistors, diodes, and LEDs. No microcontrollers or integrated circuits are involved. In fact, this clock could have been built as early as 1970, using only the technology available at that time.

All components used are high-quality and RoHS-compliant, ensuring safety and durability. The expected lifetime is extremely long for nearly all parts—except for the electrolytic capacitors, which may eventually require replacement after many years. Fortunately, these are easy to identify and replace if needed.

Another major advantage of this design is visibility: thanks to the widespread use of LEDs throughout the circuit, problems are easy to spot and diagnose. If something fails, you can typically see exactly where the issue is and fix it quickly.

The clock is meant for people who are interested in electronics—enthusiasts who don’t take ICs for granted. It’s also great for those learning electronics or anyone who simply likes how it looks.

This project started during the COVID lockdowns, when I had a lot of free time and decided to design my own transistor-based clock. That first version worked poorly and wasn’t very reliable. A couple of years later, I revisited the project and improved it significantly.

The clock’s precision depends on your local electric grid frequency, and is usually accurate to within ±20 seconds per year. Since it relies on mains frequency, it resets when the power goes out. This approach simplifies the design and reduces the component count. The fewer the components, the fewer things that can fail over time.

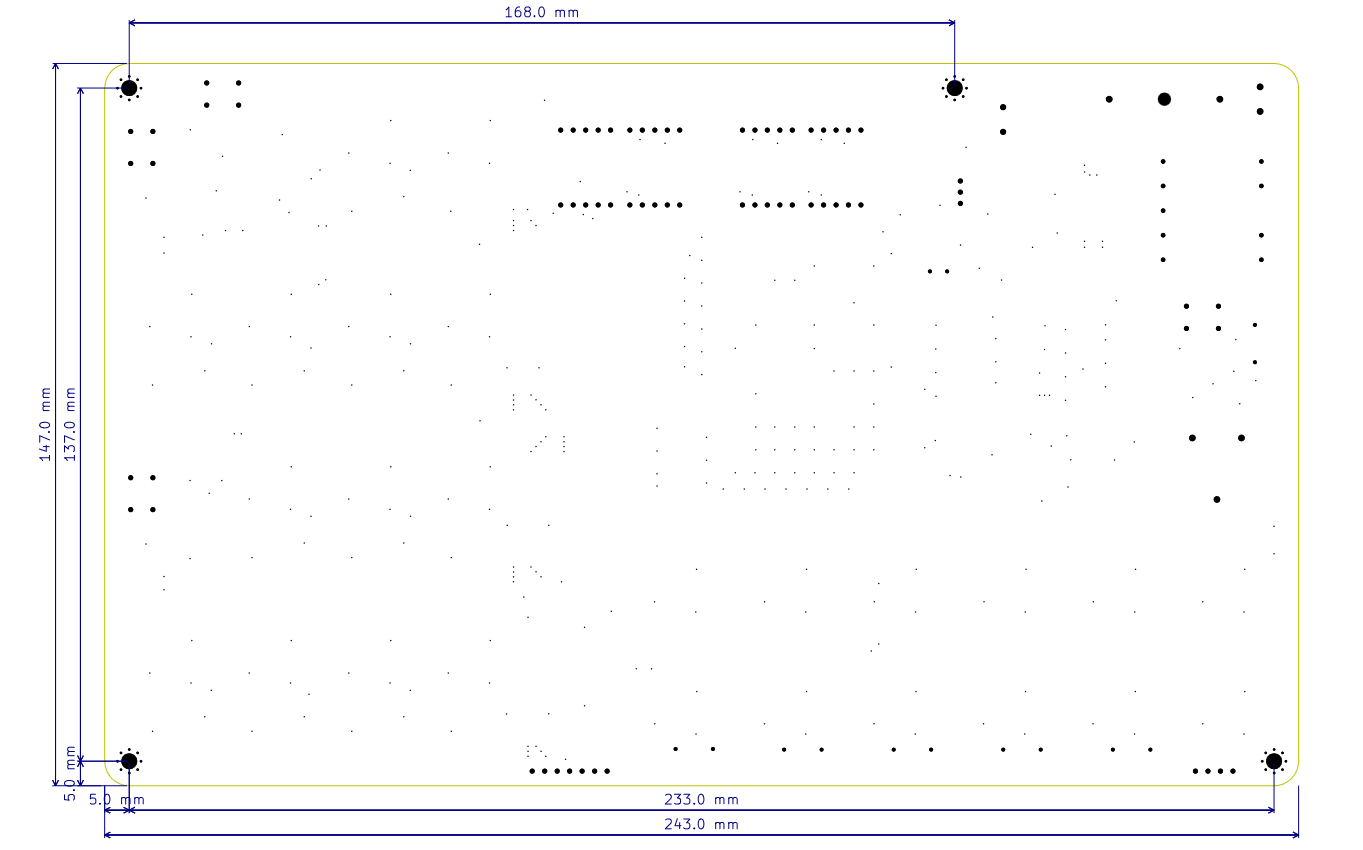

The clock is built on an 243 × 147 mm PCB that contains all necessary components. Surface-mount (SMD) components are used to reduce soldering time and manufacturing cost. While it would definitely look cooler with through-hole (THT) parts, that would double the size and take much longer to assemble.

The default version supports 220V 50Hz input. There is also an option without a transformer, allowing you to solder your own for other voltages and frequencies (check the Installation section).

If you’re not comfortable working with mains voltage, you can use a socket transformer instead.

There are other similar digital clock kits online, often sold in THT form, but they aren’t optimized for discrete components. This design uses around 800 components, while others typically use between 1200 and 1800. Links to similar projects are provided at the end.

You can mount this clock on a wall using 3M screws, which can be attached to a wooden plate or other surface and then hung.

Rendered image of the Discrete Digital Clock

For a more detailed preview of the clock internals, see the Detailed Overview.

Installation

⚠️ Installation is straightforward, but use caution, especially when working with the mains-powered version. ⚠️

220V 50Hz Transformer Version

If you’re using the mains-powered version, you must have a basic understanding of mains electricity, as it can be lethal. It’s essential to isolate the mains section of the clock (or the entire unit) to ensure safety. This version is intended for use in Europe and other regions that use 220V 50Hz power.

You will need to provide your own power cable. Connect the cable to the top right side of the clock, where the power supply connector is located.

A 30mA fuse is included with the mains version for added protection.

No Transformer Version

This version does not include a fuse or transformer, so you’ll need to purchase a PCB-mounted transformer separately, rated for your local voltage and frequency.

If you’re not comfortable working with high voltage, you can instead use a plug-in (socket) transformer.

The transformer must be rated for 6V AC and capable of supplying at least 1.9VA.

It’s recommended to use a 60mA fuse on the primary side for 110V, or a 1A fuse on the secondary side.

You also need to add resistors to the bottom counters of the minutes section to set the correct frequency.

Size

The PCB measures 243 × 147 mm and features M3 mounting holes for easy installation in enclosures or setups.

Below is a dimensioned drawing showing the main sizes of the PCB:

How to Use

When you power on the clock for the first time, it will be set to 00:00 without the colon (:) illuminated between the digits. All the counters will show zero and will not begin counting.

To activate the clock, you need to press the Reset button. This feature lets you know when a power outage has occurred, as the clock will remain at 00:00 until manually reset.

You can set the time using the following buttons:

- M (bottom left) to set minutes

- H (top left) to set hours

To set the seconds accurately, press the Reset button and release it exactly at 0 seconds (e.g., using another clock or stopwatch as reference).

Connectivity / Add-ons

The clock has two connectors at the bottom that provide access to the time signal and PWM output for the display. You can refer to the pinout diagram in the Detailed Overview to identify each pin.

These connectors can also be used to expand the clock’s functionality with features such as an alarm, day/date/year display, stopwatch, and more.

You can also connect buttons to a microcontroller like an ESP32, so the clock can be automatically set up every time it resets.

More Pictures

Pictures can be found here: Pictures